On average, homeowners remodel 10.2 million kitchens each year. That’s a lot of countertops being replaced! One of the key decisions any homeowner must make during their remodel is what material they want to use for their new countertop. This is no small challenge given there are many types of countertops to consider.

Quartz countertops are an increasingly popular option these days. They are beautiful, durable, and easy to take care of, making them a great choice for many homeowners. What you may not know is the material used in these countertops is man-made. Unlike granite or marble, quartz counters are a mixture of different materials. This means manufacturers can create unlimited designs and colors, so you’ll have many options to choose from if you decide to go with a quartz countertop.

Now that you know that, you’re probably wondering how these countertops are made. Let’s Dive In!

Where Does Natural Quartz Come From?

Quartz is a naturally occurring mineral commonly found in many types of rocks. This includes the igneous, metamorphic, and sedimentary rocks you probably learned about in your high school science class.

Because quartz is a very hard material, it does not erode like the surrounding rock material. As a result, over time the rocky material erodes and leaves the quartz behind. You’ve probably seen this before. Most white sandy beaches are made of quartz eroded out of rock.

While pure quartz is transparent in color, many types of quartz contain other inclusions that change the color of the quartz, with colors varying from white, gray, pink, and purple. It is often mined from veins found beneath the surface of the earth.

How Are Quartz Countertops Made?

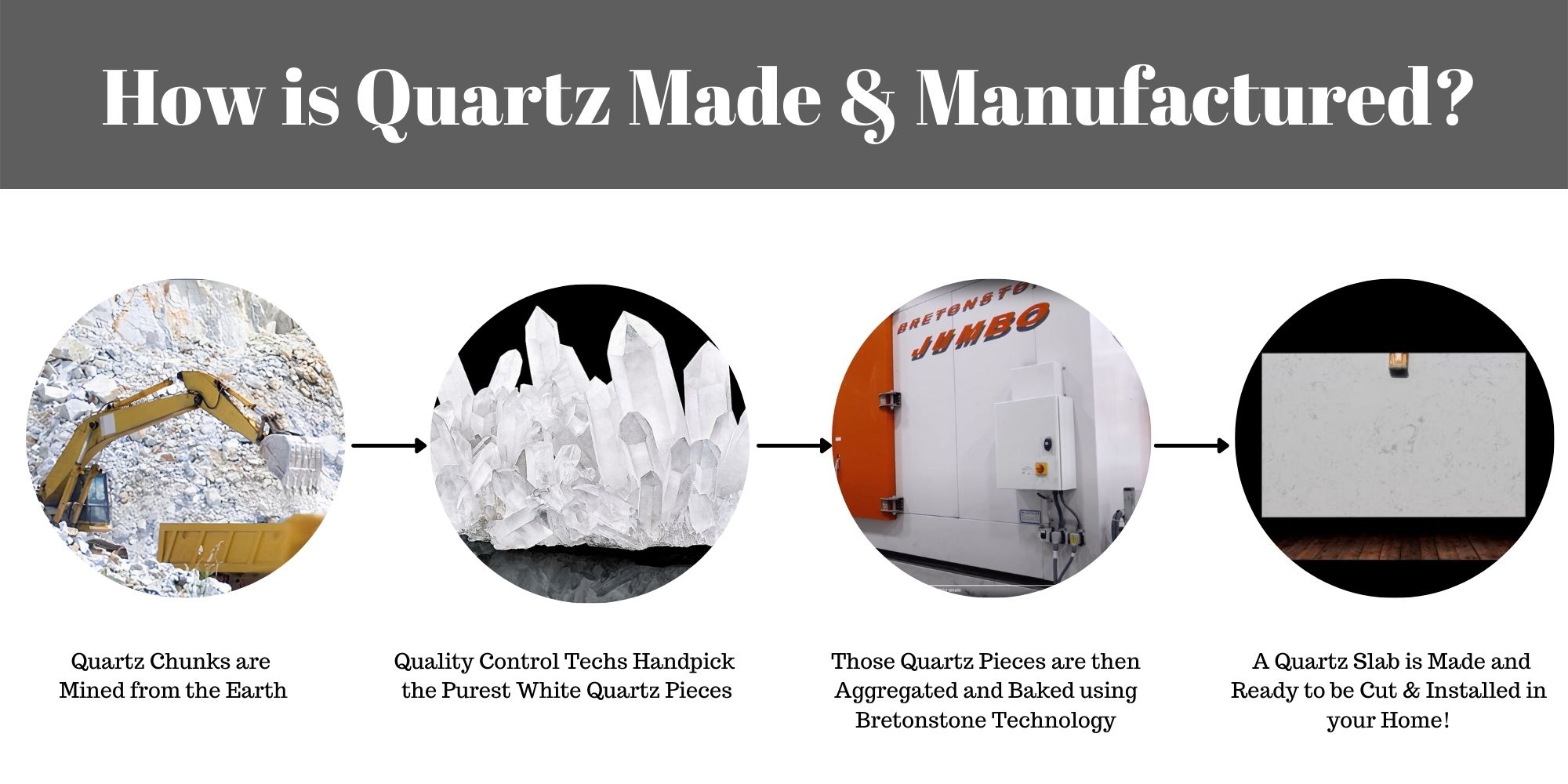

A lot of people love Quartz but are always asking, How are Quartz Countertops Manufactured? Quartz Slabs are made & manufactured using Bretonstone Technology, a process that many different quartz manufacturers employ to create the finest quartz slabs known to man.

The process starts when Pure White Quartz is mined from the Earth. The quarried pieces of Quartz then make their way to Manufacturing Facilities Next, Quality Control Technicians sort the quartz into varying shades of white, choosing only the highest quality and pure white pieces to be made into quartz slabs. These hand-selected pieces of quartz are then ground down into varying sizes, from Bean-sized chunks, all the way down to Sand, and the varying sediment levels between.

Once this is complete, the quartz pieces are aggregated together using the Bretonstone technology as mentioned above. Binder is added to the mixture, while air is simultaneously vacuumed out of the mixture through vibration. After all the air has been vacuumed out, the slabs are then pressed into the desired slab sizes and baked at high heat. This is what creates Slabs that are denser than traditional Granite Slabs, while also being Non-Porous.

This manufacturing process, used by almost every Quartz Countertop Manufacturers, ensures the gorgeous natural colors of the design are locked in within every inch of the material—creating unparalleled consistency from piece to piece. And because the slabs are kiln-fired at nearly 2,200 degrees Fahrenheit, all surfaces resist stains and scratches better than any other natural quartz while providing stellar stain protection from spills or contact with various household objects.

What are the Benefits of Quartz Countertops?

Now that you know what goes into making the countertops, you’re probably wondering what the benefits of using this material are. The good news is that there are many benefits to selecting quartz as the material used in your next countertop. Let’s review them.

As mentioned, countertops made of quartz are non-porous and resist stains, mold, and mildew. This means they’re easy to clean and germ-free. A very important property for use in kitchens where they’ll be exposed to moisture, bacteria, and germs. They make incredibly durable counters that can stand up to a lot of wear and tear in the years to come. If you have a home with kids, quartz is a great choice for your kitchen remodel.

Another great feature of quartz countertops is that there are endless styles and colors to choose from. The wide variety of colors and patterns provides many options which can easily fit into your kitchen design. You’ll want to bring home some samples from a showroom to see how the various colors and designs fit into your kitchen. If none of these work for you there’s always the option of having a custom design made to meet your need.

While quartz is one of the more expensive countertop materials, it provides many benefits and not only looks great but will also add value to your home. It’s no wonder quartz countertops are so popular among homeowners remodeling their kitchens.

Turning Quartz into Kitchen Countertops

Now to the part we’ve all been waiting for! Turning Quartz Slabs into Quartz Countertops. Now that you know how Quartz as a building material is made, now we can dive into how we turn them into custom-fit countertops for your home.

We start our process by having one of our Design Reps assess your Project and take some rough measurements for pricing purposes. From there, if you decide to use International Granite and Stone for your project, we send out our highly skilled Laser Template Technician. He will set up markers in select spots to create a to-scale, digital rendering on your Kitchen Layout. Once finalized, this then goes to our Programming Department, and your Material is ordered. We then Asses the Laser Template that we took, and figure out yield and layout based on your patterning and project layout. From there, your Project is then translated into coding that gets sent to our Computer Numerical Control (CNC) Machinery. The selected material is then loaded onto the CNC’s cutting table, and the Machine goes to work!

CNC machinery, plus laser templating gives us almost exact measurements of your space, making for a perfect fit when we come to Install the New Countertops in your Home! After being cut, the pieces then get the appropriate edge work cut and polished, the countertops are then quality control inspected, and loaded up for delivery and installation!

Ready to Get Started?

Now you know all about the process of making quartz countertops. You also know why they offer benefits no other counter material can match. So how do you get started with your kitchen remodel?

That’s easy. If you’re thinking about remodeling your kitchen, we’re here to help. From design to installation, our experts can help you every step of the way. We even offer free in-home consultations with a skilled designer.

Your in-home design consultant will help you envision and design your new kitchen look. From creating a customized plan to ordering materials and scheduling installation, your in-home advisor will handle it all.

Contact us today and we’ll help you find the perfect countertops to complete your dream kitchen with a FREE In-Home Design Consultation.

Lorem ipsum dolor sit amet, consectetuer adipiscing elit, sed diam nonummy nibh euismod tincidunt ut laoreet dolore magna aliquam erat volutpat.

[/col]