International Granite and Stone

The Best Countertop Experts Serving Tampa Bay and Beyond – IGS Countertops.

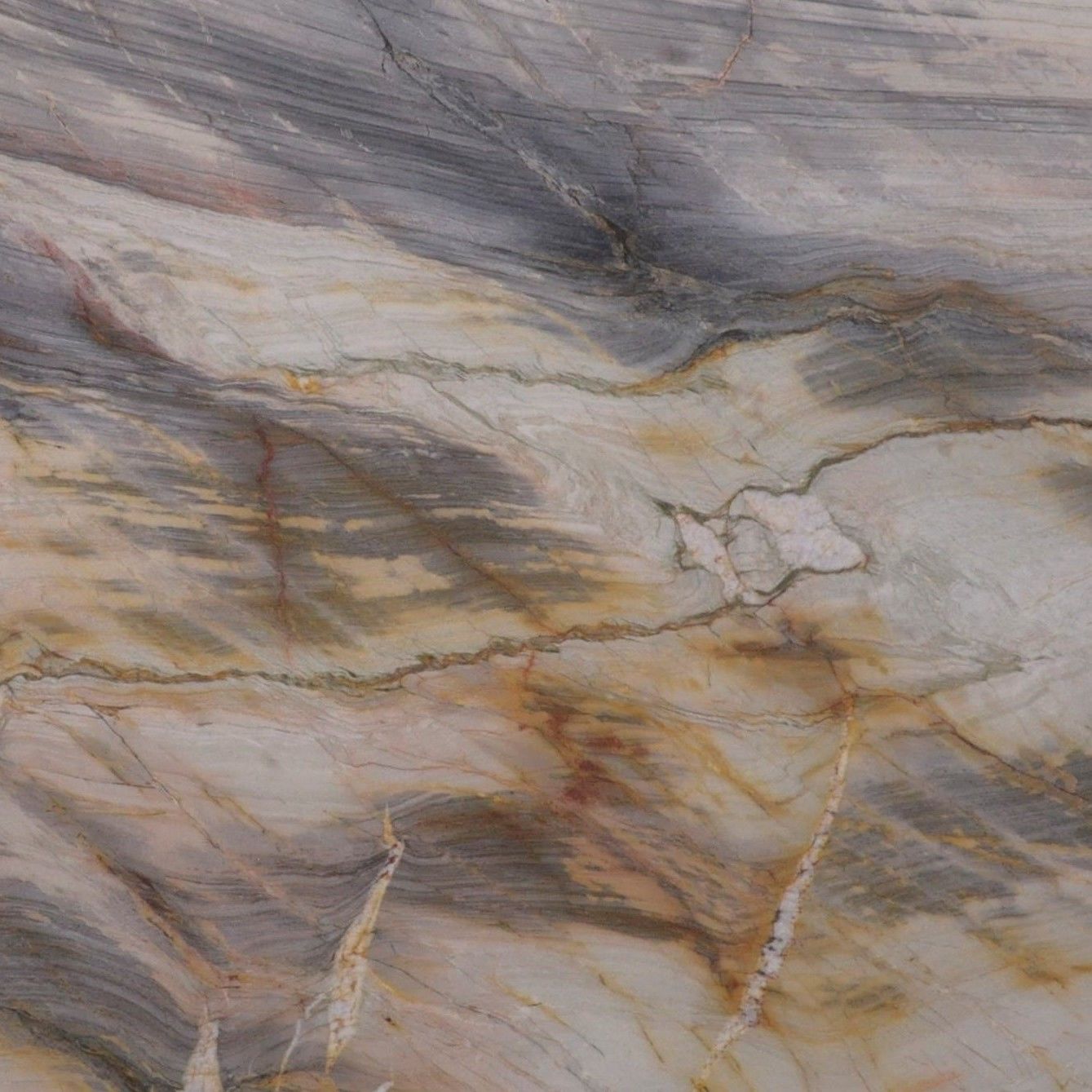

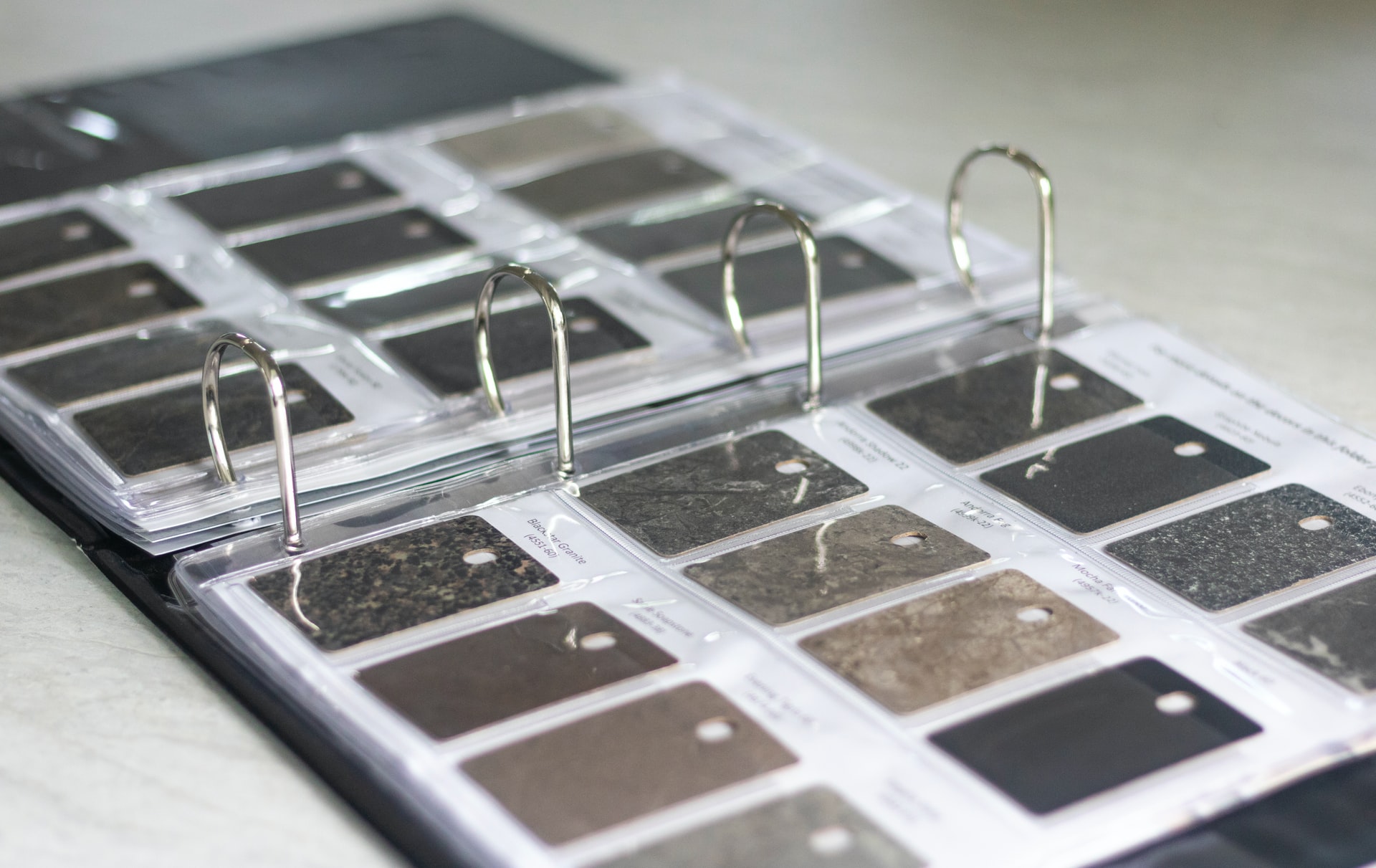

IGS Countertops delivers top-notch quartz, granite, and marble installations across Tampa Bay, Sarasota, and The Villages. Trust our experts for superior craftsmanship and personalized service in every custom countertop project.